Introduction

The Lightweight Competence Center aims to be a reference in the development of multimaterial manufacturing technologies for the automotive industry. The Center includes three distinctive areas to tackle lightweight strategic projects:

Composite

Carbon and glass fiber reinforced polymers are used in semi-structural and structural parts to provide high performance and reduced weight.

SMC parts offer substantial weight reduction, good mechanical properties, superior corrosion resistance, design flexibility by accomodating shape complexity and reduced manufacturing complexity through part integration.

The Composite Area includes a reinforced polymer characterization system, a preform cutting table, a Sheet Molding Compound cell and a post-processing center

Aluminum

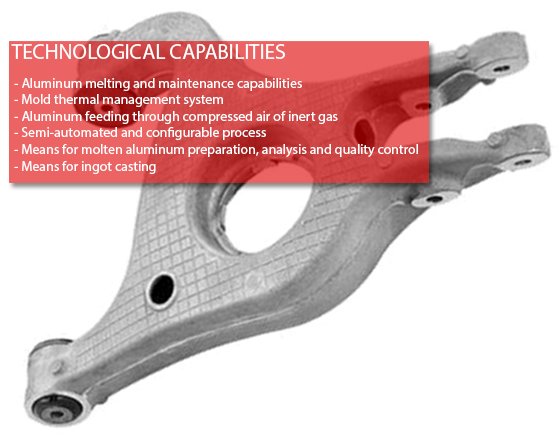

Aluminum is used in powertrain, suspension and structural parts for safer and lighter vehicles

LPDC parts offer very good strength values, complex geometries, high dimensional accuracy and higher material utilization

The Aluminum Area consists of a two-in-one melting and maintenance furnace, a hydraulic press, a component extraction system and a cooling tank

High Strength Steel

Stamped Steels are highly used in body in white and chassis parts.

HSS cold and hot stamped parts offer lighter and safer properties than conventional stamped steels.

The HSS Area includes a servo-actuated press allowing to program the position, speed and travel curves of the press to carry out different manufacturing processes, such as, special-blanking and multispeed manufacturing.

Domain Areas

Material characterization

Advanced materials and product characterization

Product Design & analysis

New and advanced materials-focused design and analysis

Tooling

Tooling and other elements: dies, cooling-heating systems, etc.

Manufacturing

Short series and prototype manufacturing and post-processing

Joining Technologies

Lightwieght and advanced multimaterial joining technologies.

Added value services

Competitive Intelligence and specialized training